Concrete Joint Sealing and Crack Repair

We fix cracks in:

Walls

Foundations

Slabs

Floors

Garages

Footers

Patios

Block Walls

Pools

Bowed Walls

Walkways

Concrete Structures

Crack Stitches

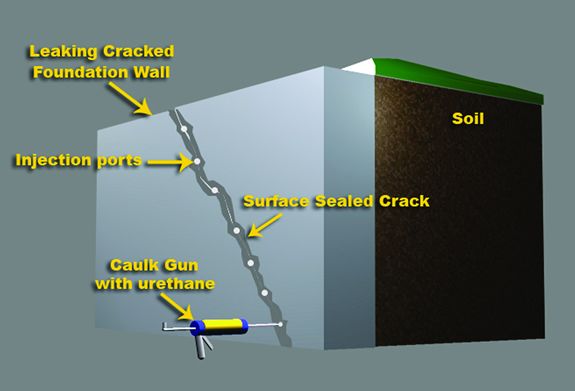

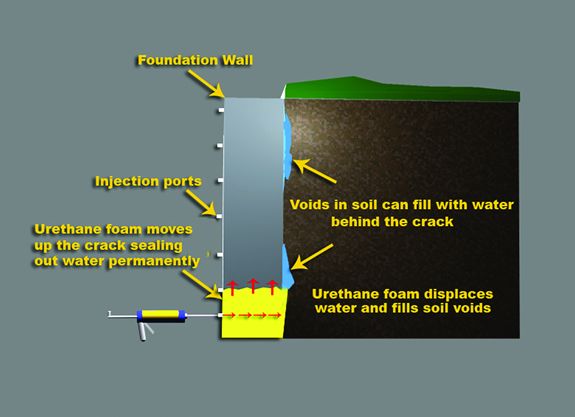

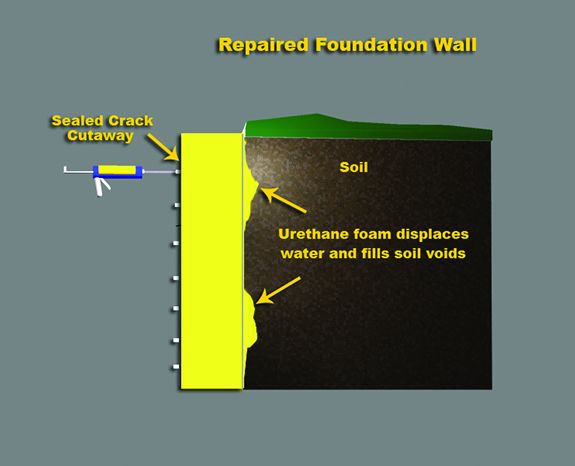

Repairing Cracks with Epoxy & Polyurethane Injection

Cracks in foundation walls can unnerve even the savviest homeowners, as they cause immediate concern about foundation issues. However, not all cracked walls indicate a severe problem. The fact is — concrete cracks. Usually, wall cracks are common shrinkage cracks that occur as the concrete cures. These cracks are typically vertical and usually less than 1/16″ wide. They are quite different from structural or settlement cracks which can happen due to differential loading, lateral pressure, or from vertical movement due to soil shrinkage.

Regardless of which type you have, it’s important to find the cause of the crack, repair it properly, and prevent future cracks from forming. When necessary, we add a structural component to the crack repair by adding carbon fiber stitches. Stronger than steel, the staples will prevent the crack from reopening even if the wall begins to move again.

No matter how your wall became cracked, we can perform a quick and effective repair. Please contact Rapid Concrete Raise & Sprays today for a free estimate to get started!